BIM Implementation Consultation

We helped leading brands implement and improve how they use BIM to

1.

Deploy BIM in Any Industry

EOS Labs has ample BIM implementation experience with major corporations across North America, Europe and MENA.

2.

Shorten Your BIM Learning Curve

Avoid costly mistakes during the BIM implementation process, saving thousands of hours and dollars.

3.

Improve the ROI of Your Buildings

Reduce your monthly O&M costs and optimize major investments by managing your building with a BIM digital twin.

Why EOS?

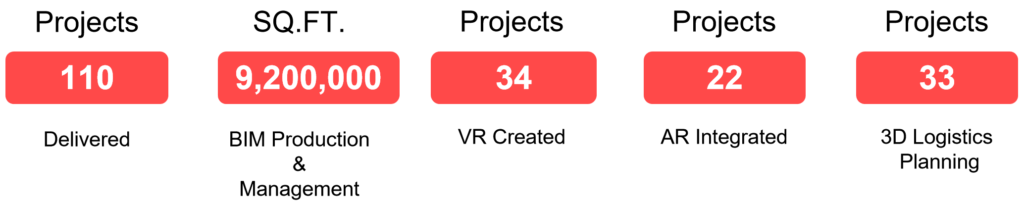

110

9200000

34

33

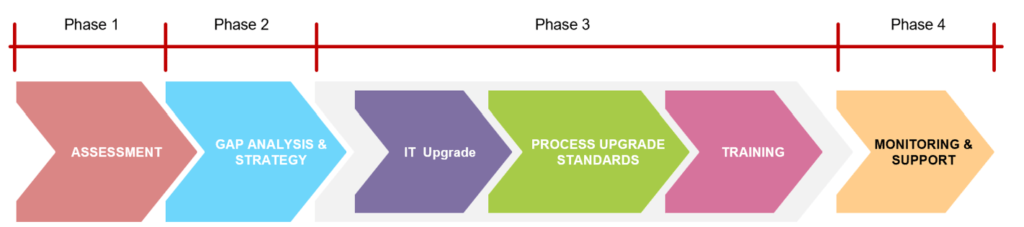

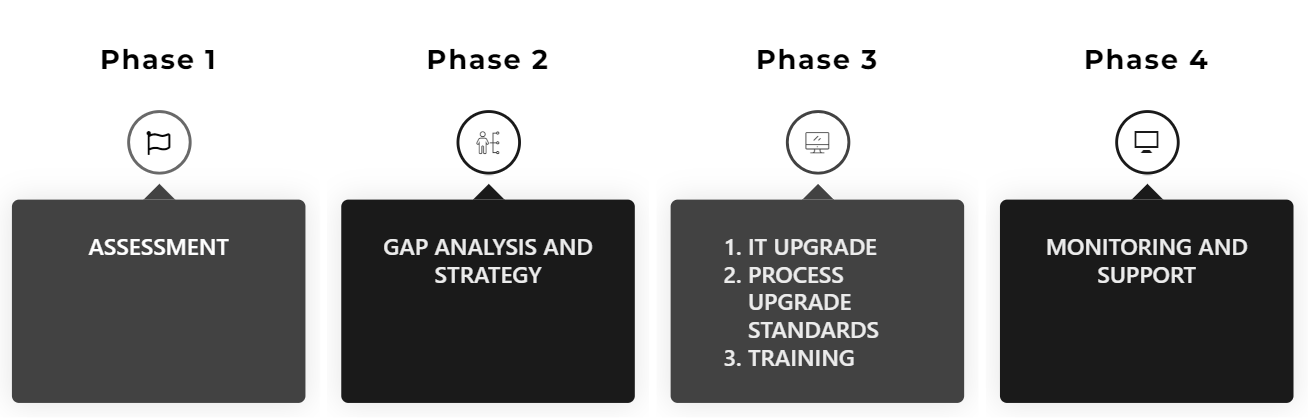

Our BIM Implementation Process

ASSESSMENT

STRATEGY

- IT UPGRADE

- PROCESS UPGRADE STANDARDS

- TRAINING

SUPPORT

Building Information Modeling (BIM) is a methodology that relies on digital building models, which contain detailed information about their components and systems. BIM is often regarded as a design and planning tool, but it can also be used to manage buildings throughout their entire life cycle:

-

BIM can be used to optimize the construction process, and to manage building maintenance after starting operations.

-

Having an updated digital model is especially useful when planning major renovations or building system upgrades.

-

BIM reduces the ownership cost of buildings while increasing their ROI, since you can make decisions based on accurate and updated information.

EOS Labs has sample experience with BIM methodologies and software. Our team of experts can help you implement BIM across your building portfolio. If your organization is new to BIM, we can guide you through the initial implementation and shorten the learning curve for your technical staff. EOS Labs can also help your company improve existing BIM capabilities.

Need a Financial Advice for

BIM Projects?

How Does Building Information Modeling Work?

Traditional building designs use 2D drawings with annotations and installation details, which are complemented by technical specifications. These document formats have been used for decades in construction projects, but they have several limitations:

-

2D drawings have a limited capacity to represent 3D objects like buildings, and clashes between components can remain undetected until the construction stage.

-

Modifying traditional construction documents is a time-consuming process, and errors are more likely when multiple documents must be updated manually.

-

2D drawings that represent complex building systems can be difficult to understand, unless you have a technical background.

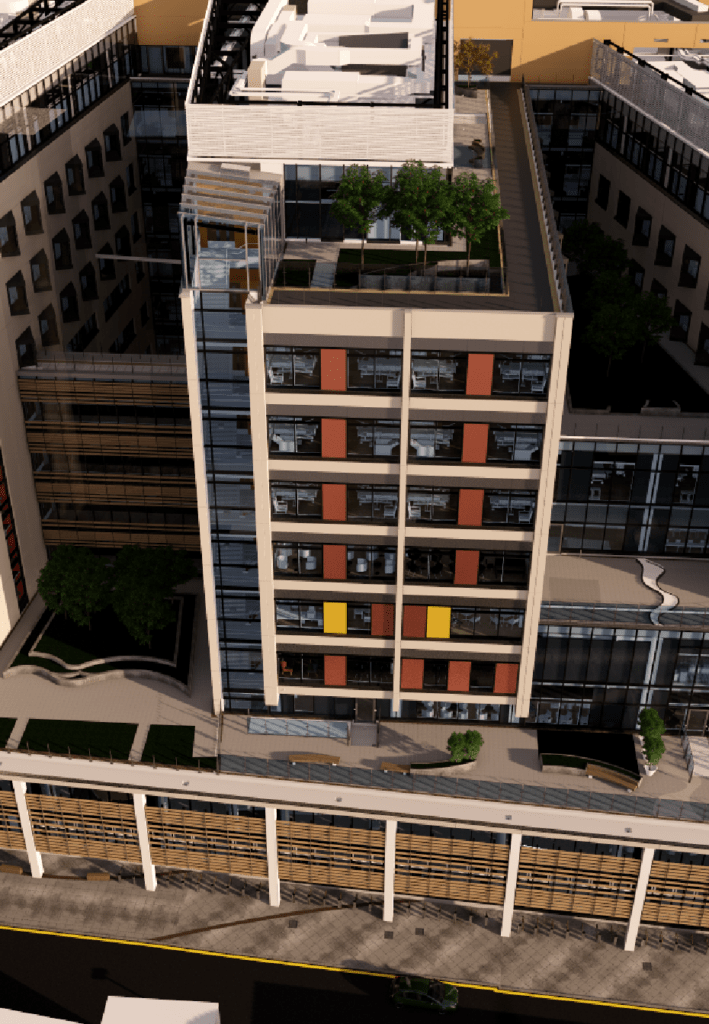

Creating a geometric 3D model of your building project is one of the first steps when using BIM. Unlike traditional 2D drawings, a 3D model reflects the exact appearance of your building and its key systems. For this reason, BIM models are more useful when marketing a project among potential investors or tenants.

3D models are especially helpful when designing areas such as mechanical and electrical rooms, which often contain different types of equipment in a vertical configuration.

-

Specifying these installations on 2D drawings can be very difficult, since components appear stacked together when shown in overhead views.

-

To avoid confusion in these cases, design engineers create a separate 2D drawing for each building system. This solution makes construction drawings easier to understand, but the design process becomes slower.

BIM is associated with 3D modeling, but this is only one aspect of BIM methodologies. Once a 3D building model has been created, design engineers can add detailed information about each component, including technical specifications and cost data.

-

With a completed BIM model, you can visualize each building system from different viewpoints, and display detailed information about each component.

-

2D drawings have limited space to show this type of data, and they must be complemented with separate specification documents and bills or materials.

-

BIM models are often described as “4D models”, since they display the three spatial dimensions + detailed information about each component.

If 2D drawings and technical specifications are needed for project permitting or any other purposes, they can be generated automatically from a BIM model. These documents are also updated automatically if the main building model is edited. In the traditional design process, each document must be updated individually to reflect design changes, and this process can demand many hours of work.

BIM can also be implemented in buildings that were not originally designed with this method. Existing buildings can be modeled using existing construction documents as reference, and the model is then completed based on the current condition of building systems.

Using BIM to Manage the Construction Stage

BIM software can be used to simulate the construction process, providing a detailed breakdown of material and labor costs over time. Simulations can also reveal bottlenecks in the construction process, which may not be evident when looking at the completed building design. A BIM model is not only useful for building owners and their staff, but also for the contractors involved in the project:

-

This information is also available when using 2D drawings and specification documents, but BIM provides a much more accessible format.

-

The building model provides an accurate representation of each system, and detailed information about each component.

-

BIM software detects clashes between different building systems automatically. By fixing these issues during the design stage, you avoid expensive changes during construction.

BIM models are helpful when specialty contractors must work in areas that combine different building systems, such as chiller plants and boiler rooms. Contractors can visualize the exact layout of the equipment and components they must install, while being aware of the locations of other components. Without a BIM model, coordinating specialty contractors can be a major challenge for project managers.

Using BIM for Facility Operation and Maintenance

BIM is useful throughout the life cycle of a building, and this includes operation and maintenance. The BIM model provides a detailed layout of all building systems, and this is especially useful for maintenance departments:

-

Your technical staff can open the BIM model on a tablet at any time. There is no need to carry a printed set of construction drawings.

-

The exact locations of all equipment and components are displayed in a highly detailed model, simplifying inspections and maintenance tasks.

Your maintenance personnel can add notes directly to the components displayed on the BIM model after completing a task. This information can be used to purchase parts and schedule replacements more efficiently. You can also use sensors to monitor key equipment 24/7, and any issues that need attention from your maintenance staff are displayed on the BIM model as soon as they are detected

BIM models can also be used as a starting point for building expansions, equipment upgrades and major renovations. Instead of designing a project from zero, changes can be implemented digitally on an existing model. This is especially useful when working with hidden components, such as plumbing lines embedded in walls or HVAC ducts above a dropped ceiling. Building upgrades can be planned with minimal inspections, since you have a digital model that reflects the current condition of all building systems.

EOS Labs has a team of consultants with more than 10 years of experience, and we can help you implement BIM as a portfolio management tool. BIM methodologies and software can help you improve the ROI and profitability of your real estate assets.

Using BIM for Clash Detection and Resolution

Automatic clash detection is one of the most useful features offered by BIM software. Since building components are modeled in 3D space, the software can detect when two objects have overlapping locations. The software can also send automatic notifications for the design engineers in charge of the clashing systems, and they can relocate components as needed:

-

Your technical staff can open the BIM model on a tablet at any time. There is no need to carry a printed set of construction drawings.

-

The exact locations of all equipment and components are displayed in a highly detailed model, simplifying inspections and maintenance tasks.

Relocating electrical conduit would make more sense in this example, since HVAC ducts are heavier and larger. Changing the conduit layout to avoid HVAC ducts is more cost-effective than changing the duct layout to avoid conduit runs.

Thanks to its automatic clash detection feature, BIM software can help you avoid expensive rework during construction:

-

When clashes are detected during the design stage, you only need to modify a digital model (as opposed to an actual building).

-

The cost involved is limited to the work hours required to implement design changes.

-

Once you reach the construction stage, each modification comes with a high material and labor cost.

-

Changes during the construction stage also increase the material waste produced by your project.

BIM is a powerful cost optimization tool, since the impact of different design options can be quantified automatically. This is not feasible when using traditional design methods: bills of materials must be recalculated manually with each change in the building design, and comparing different options can take a long time.